Feed cost accounts for +70% of the breeding operation costs. Data on feed consumption plays big part in the Profit and Loss analysis of breeding operation. Accurate and real-time data of silo feed flow is of the most importance and greatest concern to farm managers.

Feeds are stored in bulk in silos outside the raising houses. The capacity of each silo is in line with its breeding scale, usually at a level of 1-2 days’ consumption (with a volume less than one day, extra workload for feed transportation will incur, while with a volume more than 2 days, the feed freshness will be compromised). The feed volume in the silo keeps changing due to its centralized addition and real-time consumption.

Silos with a height of +5m and weight of 5~40 tons are usually installed in the open air, big errors in data reading (+-10%) are common & often due to many reasons:

1. The load cell under constant pressure tends to experience fatigue and lose sensitivity from time to time, and presents big errors in data reading

2. Changes in season, temperature and climate (wind, rain, and snow) often cause changes in silo shape and position, leading to inaccurate data reading.

3. The vibrations of pipes for feed inflow/outflow, big conveyors or other equipment often cause data reading to jump, making it hard for sensors to get valid reading

Silo-weighing data acquisition is so crucial for modern breeding farms, but the weighing systems commonly used today cannot provide farm managers with an accurate and reliable data basis for performance analysis due to big weighing errors, costly and time-consuming manual calibration, and inaccurate data reading and transmission.

●1st Generation:

traditional weighing equipment, an electronic scale composed of load cells and display instrument;

●2nd Generation:

with data transmission function, composed of load cells, display instrument and DTU (Data Transmission Unit);

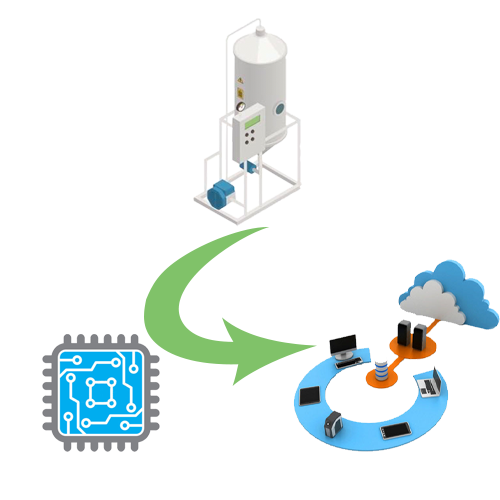

●3rd Generation:

integrated with data collection, processing, and transmission capabilities, and powered with smart algorithms, composed of Load Cells, Intelligent Controller and Cloud Computing.

WitGood is the 1st Intelligent Silo Weighing System,Widely Adopted by Livestock Industry.

WitGood Intelligent Silo Weighing Solution applies next generation technologies including Intelligent Algorithms, Cloud Computing and Smart IoT Platform, delivers Precise weighing data without tedious manual calibration, and solves all problems derived from the traditional weighing system.

Except WitGood, all other prevailing brands such as Mettler Toledo of Switzerland, Scaime of France, and HBM of Germany adopt traditional weighing system.

WitGood satisfies the needs of modern breeding farms and have been successfully adopted by +100 agriculture enterprises across China.

1-437-268-7072