Our core values are innovation, integrity and growth. Our team is made up of people from all backgrounds and experiences. We welcome anyone eager to learn, able to think outside the box, and willing to take on new challenges. We strive to create a culture that fosters trust, inclusivity, and respect in a welcoming and fun work environment. By doing so, we build stronger connections between our employees, our customers, and the community around us.

Along with paid time off, a flexible work schedule, and the ability to work remotely, we also foster professional development and provide opportunities for career growth.

We would love to have you on the team!

We’re always looking for top talent to join us.

Check out our open positions below, or feel free to contact us.

Thank you for your interest. Unfortunately, we are not hiring at this time.

Please check back as we will be looking for great people to join our team in the future.

The CEO of SWT Technologies Inc., Joy Zheng made a significant appearance at 2024 London Swine Conference on March 5th and 6th , engaging in meaningful dialogues with experts and peers on the advancements and application of agricultural technology.

The London Swine Conference is an annual event renowned for its focus on the pig farming industry, where thought leaders and practitioners come together to share insights, research, and emerging trends. The conference serves as a critical hub for discussions on enhancing productivity, sustainability, and the overall future of swine husbandry.

During the conference, Joy ZHENG, the CEO of SWT smart farm company participated in various sessions and engaged in discussions with numerous attendees, including the noteworthy guest Laura Eastwood, Swine Specialist at Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) among other distinguished speakers. They exchanged views on a range of topics, Zheng showed particular interest in the session titled "Work Smarter, Not Harder: Adoption of New Technology," which resonates closely with SWT Technology's long-term mission to seamlessly integrate advanced solutions into everyday agricultural practices.

Joy Zheng, the CEO of SWT Technologies Inc. joined the 2024 London Farm Show on March 7th , one of the industry’s most anticipated events for showcasing the latest advancements in farming technology and sustainable agricultural practices.

The London Farm Show has a storied history of being a premiere venue for farmers, agribusinesses, and industry professionals to converge and explore the newest trends, equipment, and strategies that are driving the future of farming. This year's event continued its tradition of excellence by providing a rich platform for learning, networking, and exchange of innovative ideas.

SWT presence, led by their CEO, continually attending the Show, underscored the company's commitment to pioneering new frontiers in agriculture. The CEO took part in various interactive sessions, exhibitions, and discussions that highlighted the increasing role of smart farm technology in making farming more efficient and environmentally friendly.

The livestock industry thrives on efficient resource management, which is essential for achieving success. Among the many technologies shaping this field, the silo weighing system stands out as a game-changer. This innovative solution, championed by industry leaders like SWT Technologies, is essential for monitoring feed inventories with precision, reducing waste, and optimizing operational efficiency. By leveraging cutting-edge technologies such as IoT and highly sensitive silo load cells, these systems are revolutionizing how livestock operations are managed globally. As a smart farm company, SWT is at the forefront of transforming traditional farming practices with modern solutions.

The integration of silo weighing systems into livestock farming marks a significant shift in the way feed is monitored and managed. These systems offer a sophisticated means to measure the weight of bulk materials, ensuring farmers maintain precise control over their feed inventory. With the help of silo load cells, which act as sensitive weight sensors, operators can receive real-time data on feed levels, helping them make informed decisions.

In the livestock industry, the importance of having accurate feed data cannot be overstated. Overstocking or understocking feed can lead to unnecessary expenses or productivity losses. Silo-weighing systems eliminate this uncertainty by providing accurate measurements and actionable insights. Furthermore, the data captured can reveal usage trends, allowing farmers to refine their strategies over time. This makes the technology indispensable for those seeking to maximize profitability and sustainability.

The advent of IoT (Internet of Things) has propelled the capabilities of silo weighing systems to new heights. With IoT-enabled systems, farmers now have access to a revolutionary tool: the IoT weighing machine. This integration allows for remote monitoring of feed levels and provides a range of benefits that were previously unattainable.

Farmers can now check feed inventories in real-time through their smartphones or computers, ensuring they stay informed regardless of their location. Additionally, IoT systems can be programmed to send alerts when feed levels drop below a certain threshold, preventing shortages before they occur. Historical data logging, enabled by IoT connectivity, offers farmers a comprehensive view of feed usage over time, supporting data-driven decision-making.

One of the key players in this transformation is SWT Technologies, which specializes in IoT-based weighing solutions for the livestock industry. Our systems combine advanced features with user-friendly interfaces, making them an ideal choice for modern farming operations. As a smart farm company, SWT is dedicated to delivering innovative tools that meet the evolving needs of agriculture.

A fully functional silo weighing system is composed of several vital components, each of which contributes to its accuracy and reliability. At the heart of the system are the silo load cells, which are responsible for measuring the weight of the silo's contents. These sensors are engineered to withstand harsh environments typically in agricultural settings.

Other essential components include indicator units, which display real-time weight readings, and data logging systems, which store valuable data for future analysis. Modern systems also come equipped with IoT connectivity, allowing for remote access and control. When these elements work together, the result is a seamless and efficient feed management solution.

When it comes to implementing a reliable silo weighing system, many farmers turn to SWT Technologies for their expertise and innovation. The company has earned a reputation for delivering advanced solutions that cater to the unique needs of the livestock industry. Our products not only offer precision and durability but also incorporate the latest IoT advancements to enhance usability.

SWT's commitment to quality is evident in the durability of its silo load cells, which are designed to perform reliably under tough conditions. Moreover, our ability to customize systems based on specific operational requirements ensures that every customer receives a solution tailored to their needs. With exceptional technical support and a focus on customer satisfaction, SWT has become a trusted name in the field.

As the livestock industry continues to evolve, the adoption of technologies like silo weighing systems and IoT weighing machines will play a crucial role in ensuring long-term sustainability and competitiveness. Accurate weight measurements provided by silo load cell systems allow farmers to streamline their operations, minimize waste, and optimize feed usage. Companies like SWT Technologies, a leader in the smart farm company space, are leading the way by offering solutions that combine innovation with practicality.

By embracing these advancements, the livestock sector is better positioned to tackle the challenges of modern agriculture while maintaining a focus on efficiency and profitability. The future of livestock management lies in leveraging such technologies to achieve smarter, more sustainable practices.

In modern livestock farming, precision and efficiency are crucial for success. With advancements in technology, the introduction of the smart weighing system has significantly improved operations, particularly in feed management. This article explores how SWT company is leading the charge with its innovative solutions, including silo load cells, feed management systems, and silo calibration, to optimize farming practices and ensure better productivity.

Feed management is a critical aspect of livestock farming, directly impacting the health of animals and farm profitability. Traditional methods of feed management are often manual, which can lead to inefficiencies, errors, and increased labor costs. Enter the smart weighing system: a groundbreaking solution that provides real-time data, and automatic calibrations, and integrates with broader farm management tools.

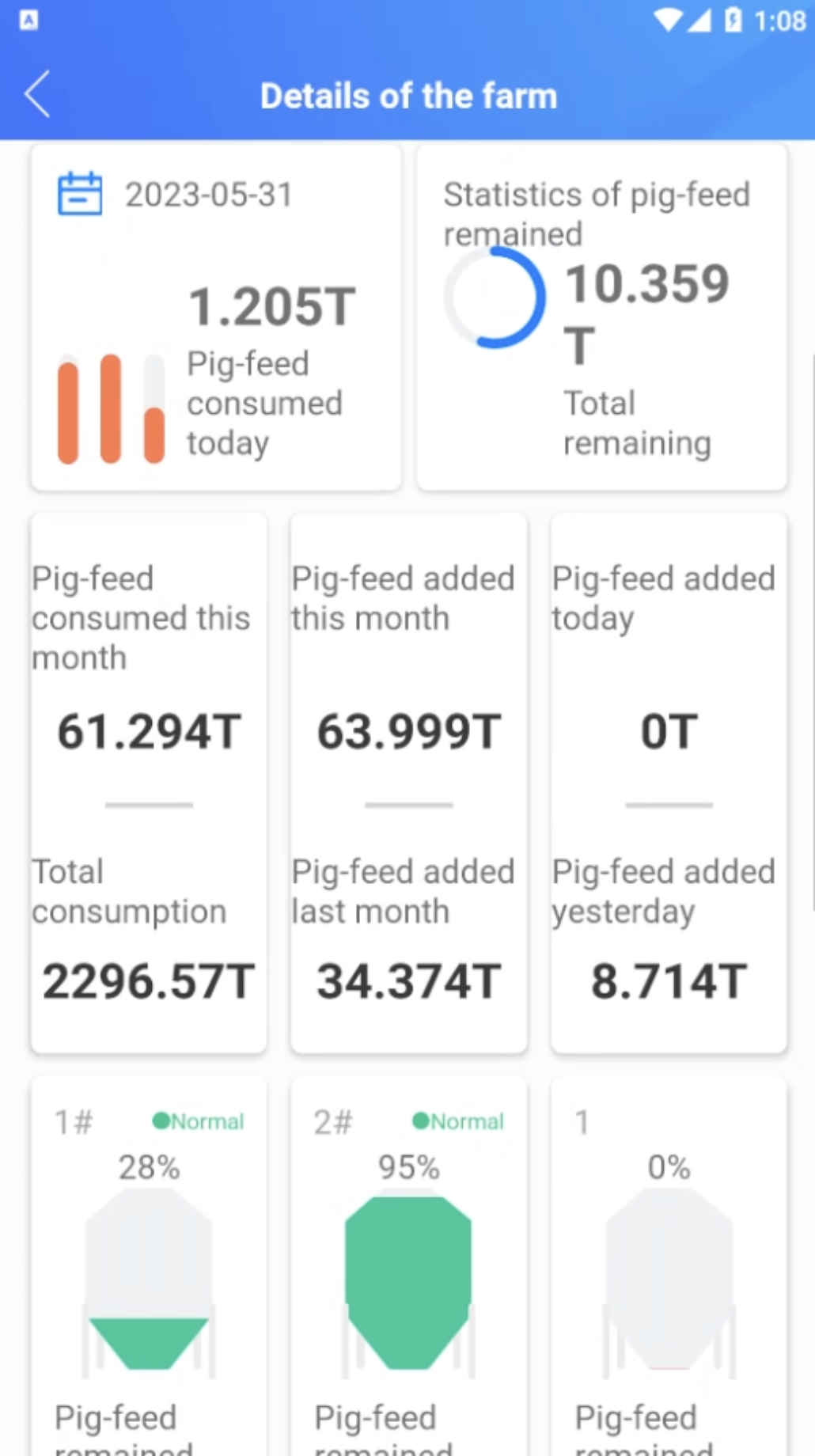

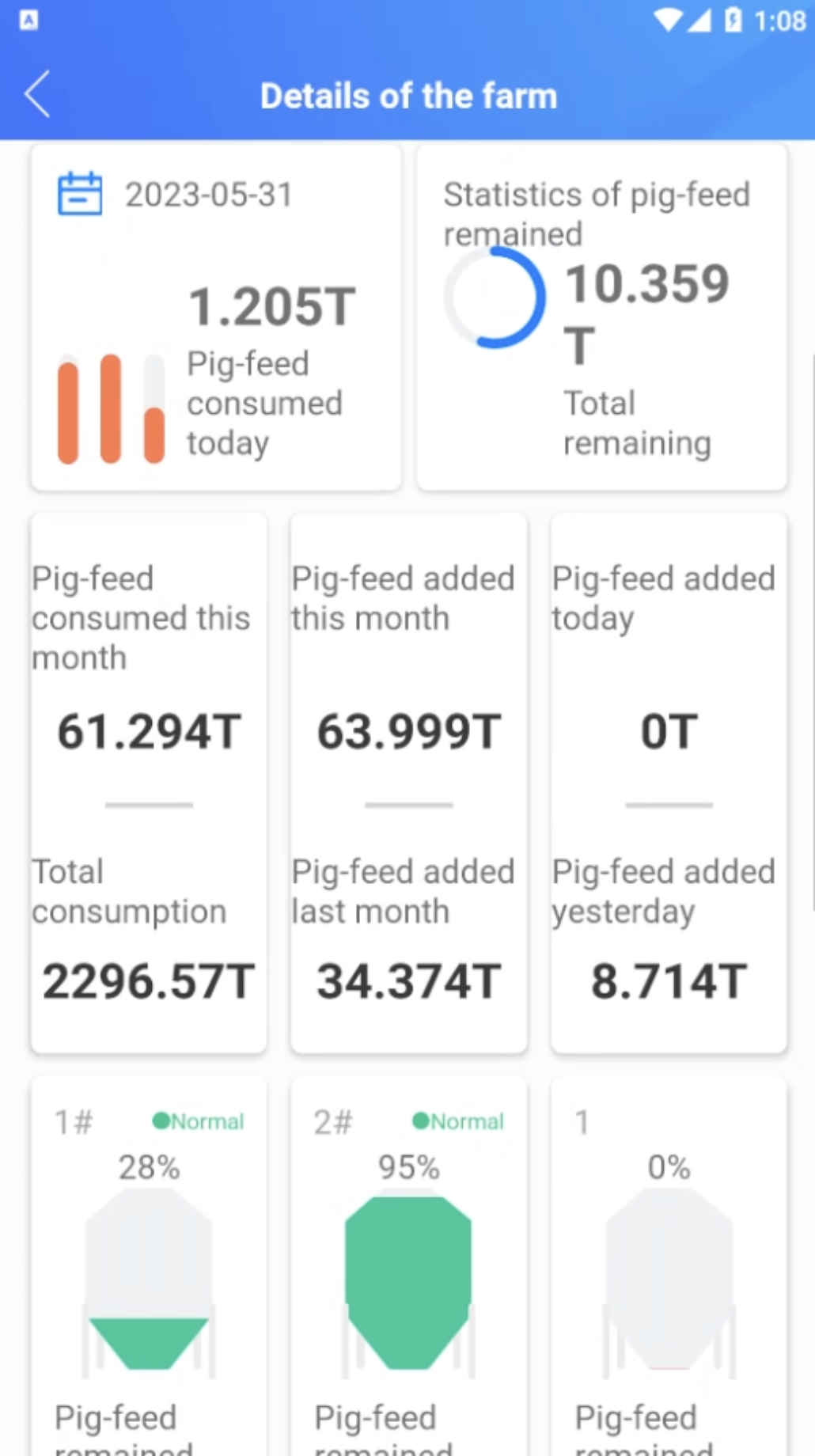

SWT's feed management systems are designed to streamline operations, allowing farmers to track feed consumption, detect abnormalities like feed waste, and even forecast feed needs. By incorporating intelligent algorithms and cloud computing, these feed management systems can analyze data to generate actionable insights for farmers. This system is also beneficial for forecasting feed requirements across different livestock batches, improving feed/meat ratio analysis, and supporting supply chain optimization.

The role of silo-load cells in modern farming cannot be overstated. These components are critical in the smart weighing system for accurately measuring the amount of feed inside silos, even in challenging environments. Whether you're storing grains, pellets, or other materials, silo load cells provide precise measurements without the need for manual recalibration.

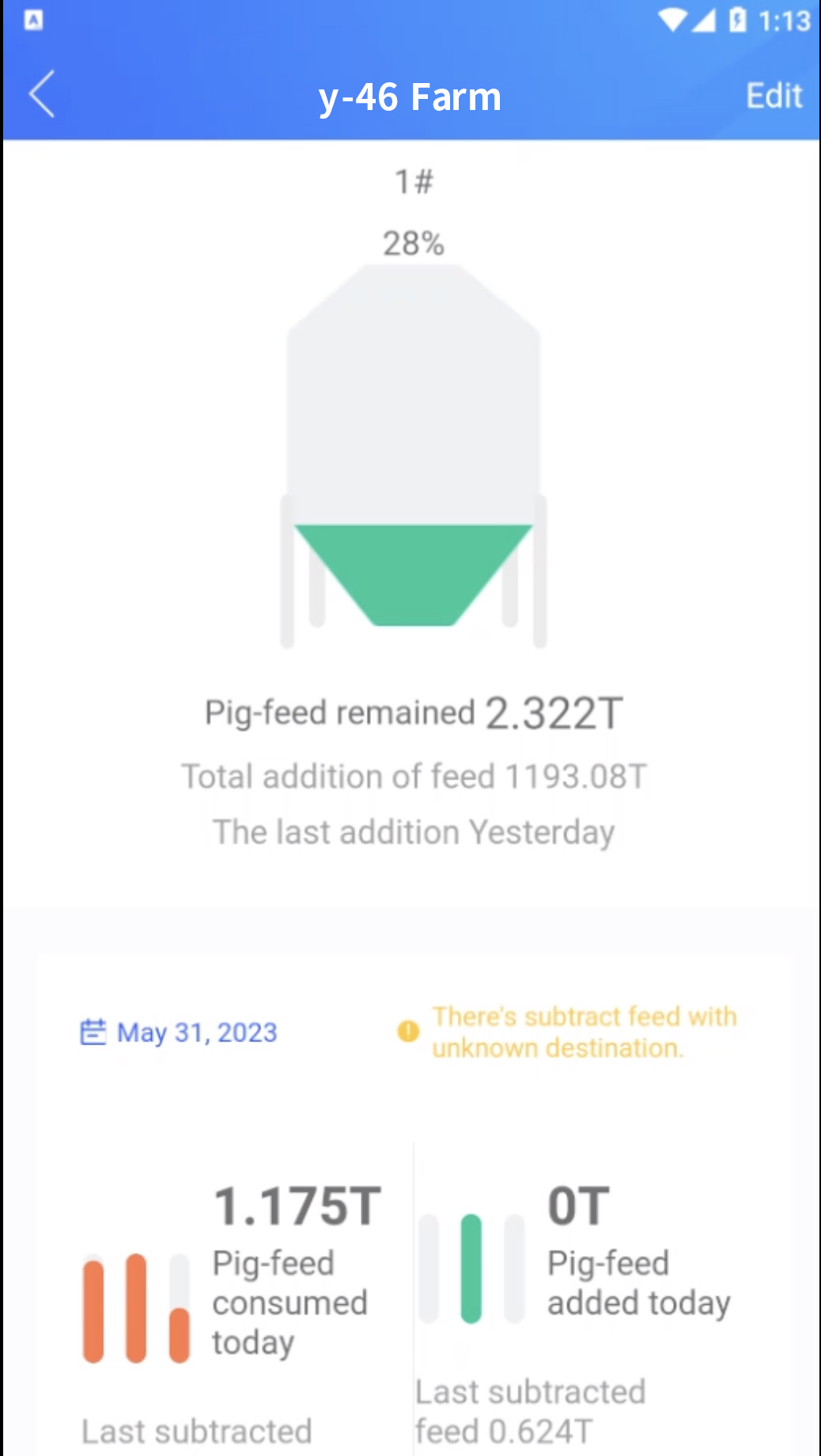

With the integration of IoT (Internet of Things) platforms, farmers can access silo data remotely, allowing for better decision-making. The ability of an SWT intelligent controller to monitor feed levels in real-time ensures that feed is distributed efficiently, and any irregularities, such as unusual waste or over-usage, can be detected and corrected promptly. This helps to optimize feed use, reduce costs, and prevent underfeeding or overfeeding issues, which can significantly impact livestock health and growth.

One of the biggest advantages of SWT's smart weighing system is its automatic silo calibration feature. Calibration is often a cumbersome task in traditional systems, requiring manual adjustments and downtime. However, with SWT’s system, calibration can be done effortlessly via a dedicated app, ensuring consistent accuracy without requiring additional labor. This feature is vital for farms that deal with varying environmental conditions, as silo weight readings can be influenced by temperature, humidity, and material type. The ability to calibrate silos on-demand ensures that the weighing system delivers accurate data regardless of the external environment, reducing the potential for errors and ensuring that the feed management system remains reliable over time.

In conclusion, the integration of a smart weighing system with advanced silo load cells, real-time monitoring, and automated silo calibration is transforming the way livestock farms manage feed and other vital resources. By adopting these technologies, farms can significantly improve efficiency, reduce waste, and ensure the health and well-being of livestock. SWT company’s innovative approach to feed management systems provides a comprehensive solution for modern farming needs, ensuring that farms are not only more efficient but also more sustainable in the long run. By embracing smart weighing systems and silo load cells, the future of precision farming is within reach, providing farmers with the tools they need to succeed in an increasingly competitive industry.

At SWT Technologies, our innovative approach to silo weighing is transforming how feed management systems operate. Our smart weighing system, equipped with high-precision weight sensors and advanced silo load cells, provides a comprehensive solution for effective feed management. By leveraging our advanced technology, you can achieve unprecedented accuracy in silo weighing, drive productivity improvements, and realize significant cost savings over time.

SWT Technologies state-of-the-art silo load cells are at the core of our advanced weighing solutions. Meticulously engineered for precision, these load cells for silos convert the weight of stored materials into highly accurate digital signals. Each silo weighing cell is designed to withstand harsh environmental conditions while maintaining a high level of sensitivity and repeatability, ensuring that even the slightest variations in load are captured. The integration of high-quality weight sensors guarantees that the data fed into your feed management systems is both reliable and actionable. This silo weighing technology not only enhances inventory accuracy but also provides real-time insights that allow operators to optimize the performance of their silo weighing applications continuously.

SWT Technologies systems are designed to seamlessly connect with feed management software, enabling operators to monitor and adjust feed levels in real time. This robust integration facilitates dynamic decision-making—automatically recalibrating the feed input based on precise, real-time data from the silo weighing process. The result is a streamlined workflow where feed management systems are more responsive, reducing the likelihood of overfilling or underfilling silos and ensuring that production processes remain uninterrupted. This smart, automated approach not only minimizes manual intervention but also enhances operational efficiency and safety throughout the facility.

When silos are weighed with precision, the entire supply chain benefits from reliable inventory data, which is essential for scheduling feed replenishment and avoiding costly production disruptions. By deploying advanced weight sensors and robust silo load cells, SWT technology solutions provide the level of precision needed for effective inventory tracking. This accuracy enables better forecasting, reduces material waste, and supports efficient resource allocation. In a world where even minor discrepancies can lead to significant losses, our smart weighing system ensures that feed management remains error-free and consistently aligned with production demands. Ultimately, this technology supports a more resilient and agile operation, giving businesses a competitive edge in today’s dynamic market environment.

First Intelligent Silo Weighing System in Livestock Industry

Intelligent Algorithms are applied in both WitGood controller and cloud computing platform, enabling it to outperform all prevailing silo weighing brands in all aspects such as data accuracy, cost efficiency, ease of operations and digitalization of livestock farming. The benefits of remote calibrations and real-time feeding management have brought Increasing demands for WitGood under strict livestock safety and hygiene requirements post-pandemic.

Distinctive Precision and Durability

WitGood has been proven to be accurate and reliable, with no malfunction rate in the past five years, even under extreme weather in tropical oceanic areas and cold continental regions.

Smart Tool to Help Livestock Farms Migrate into Smart Agriculture

Equipped with WitGood Intelligent Silo Weighing System, livestock farms have never found it so easy to monitor real-time feed consumption by farm, silo, raising house, or batch of livestock. Just a click can perform calibration of the load cells via the WitGood App. Furthermore, WitGood is extensively compatible and can quickly fit into farms' existing systems, making a seamless transition to digital agriculture management.

WitGood load cells are specially designed for Livestock Industry, with a distinctive low error rate less than 0.5%, verified by data collected from 100+ farms over five years. Load cells for silos are manufactured with the compliance to Global Industry Standard.

Farm Group Customers

Our core values are innovation, integrity and growth. Our team is made up of people from all backgrounds and experiences. We welcome anyone eager to learn, able to think outside the box, and willing to take on new challenges. We strive to create a culture that fosters trust, inclusivity, and respect in a welcoming and fun work environment. By doing so, we build stronger connections between our employees, our customers, and the community around us.

Thank you for your interest. Unfortunately, we are not hiring at this time.

Please check back as we will be looking for great people to join our team in the future.

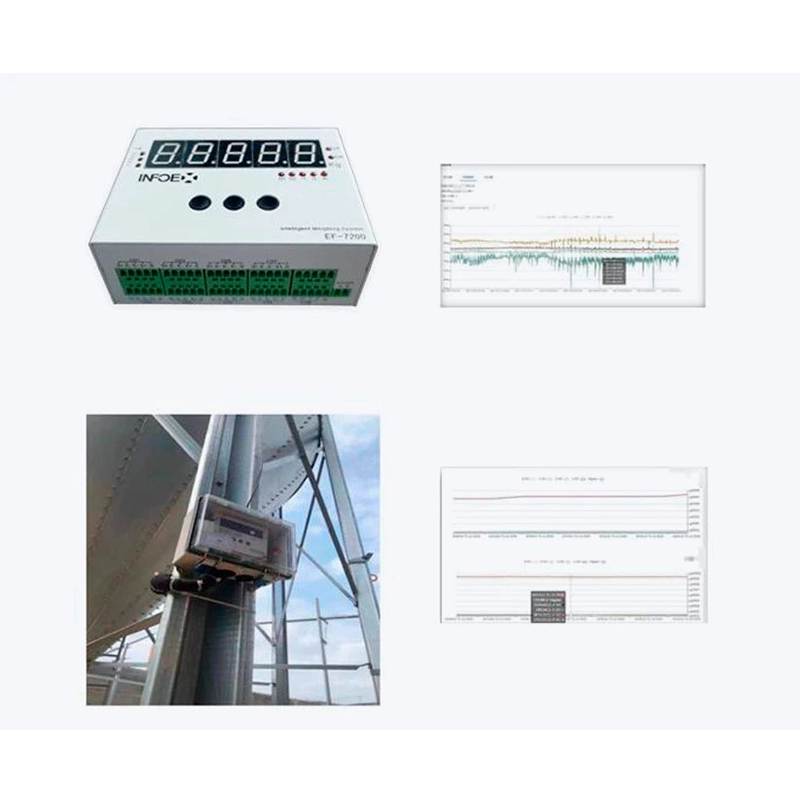

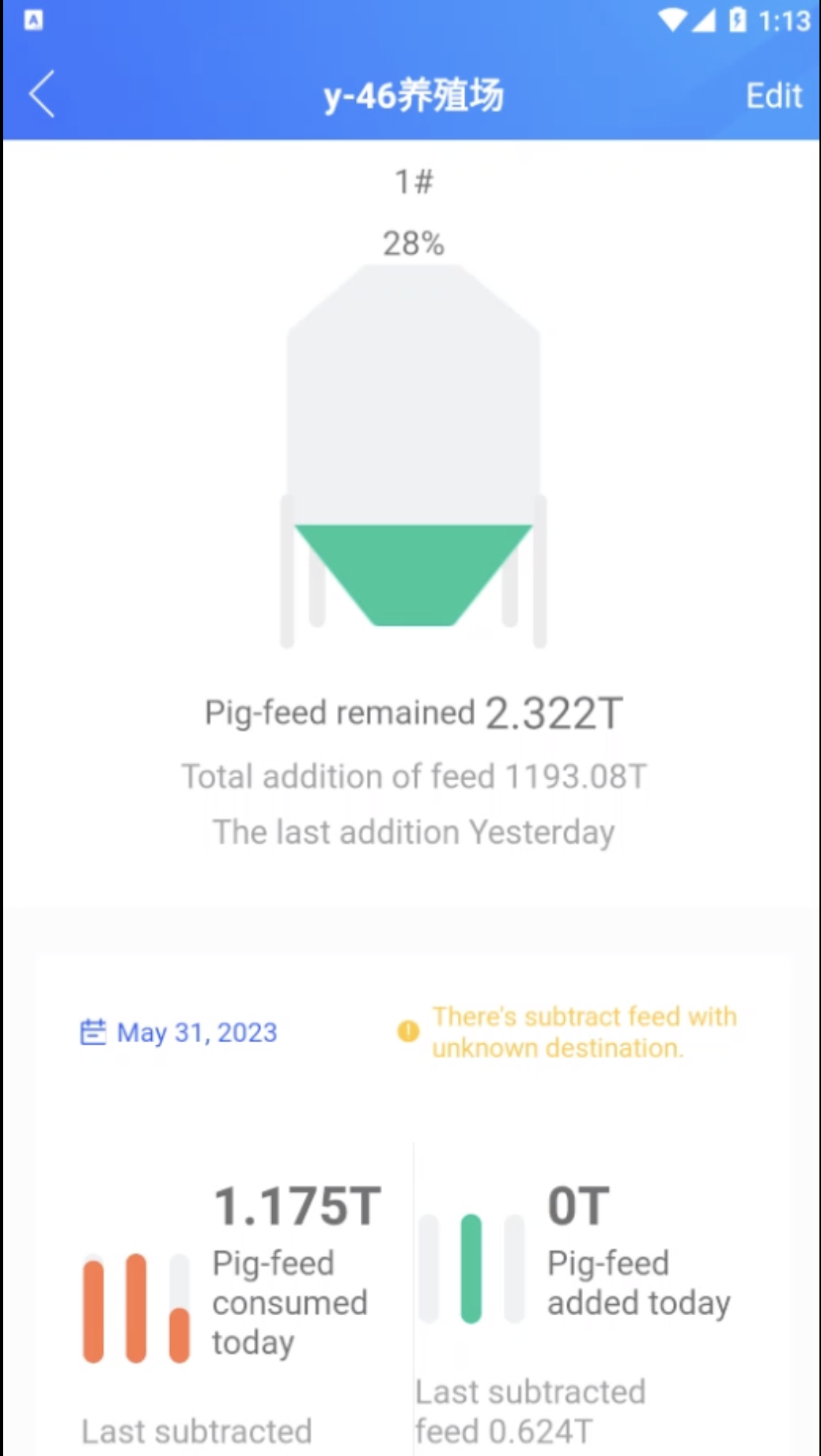

WitGood intelligent silo weighing system for pig farming is a digital and AI-based system specially designed for the swine production industry, which automatically measures and controls the amount of feed given to swine. Smart farming solutions for feed consist of load cells, a control unit with a digital display, and a cloud computing platform.

WitGood system uses high-precision load cells to measure the weight of feed as it is added to or released from the silo. The load cells automatically transmit the weight data to the control unit, which then calculates the amount of feed consumed. This data is shown on a digital display and transmitted wirelessly to computers or mobile devices in real-time.

With an intelligent algorithm model combined with intelligent tracking & filtering algorithms, and cloud computing, the WitGood system enables swine farmers to:

WitGood system filters out all major on-site interference factors such as temperature, humidity, wind, and environment pH values, etc, by applying WitGood intelligent algorithms and AI deep learning.

The WitGood system enables real-time monitoring and control of the feeding process through its feed management platform, allowing for timely adjustments as needed.

Smart push notifications will be sent to both onsite staff and farm management once an abnormal situation is detected so that troubleshooting can be performed immediately.

There will be no need for manual calibrations onsite, which usually involve tedious processes, costly labor, and operation downtime.

WitGood product feed management software can collect and analyze feeding data, providing valuable insights for optimizing feed formulation and animal performance. The data feed management software ensures that each animal receives the desired amount of feed, minimizing waste and ensuring optimal nutrition. By ensuring accurate and consistent feed intake, the feed management platform can contribute to better swine health and productivity.

WitGood system makes it effortless to generate chats and reports on feeding behaviors in different growth stages of a batch of pigs, or to compare different batches raised in the farm, assisting farmers in feed management and production planning. With its compatibility with other IoT devices, WitGood offers a smart tool for future swine farming by utilizing its data feed management software.

In summary, WitGood feed management solution will help swine farmers to:

Save cost on feed and weighing equipment maintenance

Minimize feed waste, ensure optimal nutrition, and better swine health and productivity

Enjoy the visualization and digitalization of smart swine farming

WitGood Intelligent Algorithms is combined with multi-type data correlation analysis, including Intelligent tracking algorithm, temperature compensation algorithm, and intelligent filtering algorithm. Through +100,000 online load cells and +5 years of development, WitGood Algorithms provides more powerful and accurate feeding statistics to livestock farming.

With upgraded functions and services to meet the requirements of Big Farm groups, new features covering all business levels from corporate, branch companies, breeding farms, raising houses, to silos and equipment.

Major upgrades include capabilities of:

Managing Multiple Types of Silos including peripheral silos, transferring silos, and raising house silos

Monitoring feed flows of each silo within the farm

Managing feed consumption per raising house and per batch of livestock, providing precise analysis on feed/meat and feed/egg ratio.

Managing consumption of different feed categories and different batches of same feed category

Building new report center enables users to track/compare feed statistics across farms or raising houses or across time.

Precise visualization of feed addition & consumption onsite, via mobile App and PC.

The feature of an intelligent controller is to automatically rectify data deviations caused by common disturbing factors.

Smart push notifications and automatic alerts to potential hardware failures or abnormal data for proactive troubleshooting.

Remote intelligent calibration of load cells. No need for manual calibrations, saving time and money.

Provide a smart IoT platform for seamless integration with other IoT equipments and applications. No hassles to hopping around multiple interfaces.

Provide farm owners/managers with handy digital management tools.

Build reliable data basis for critical operation analysis such as feed/meat ratio and feed/egg ratio analysis.

Support automatic generation of feed purchasing order for farms by feed category, aligning feed consumption with feed production in the livestock industry supply chain.

SWT Technology applies cutting edge algorithms and Cloud computing technologies, strives to help livestock enterprises build convenient, intelligent and reliable data collection & analysis capabilities, ultimately achieving their goals in smart agriculture and data-driven management.

Quality WitGood equipments programmed with top notch algorithms and technologies, sufficient supply, flexible delivery, FCC/CSA certified (need to confirm).

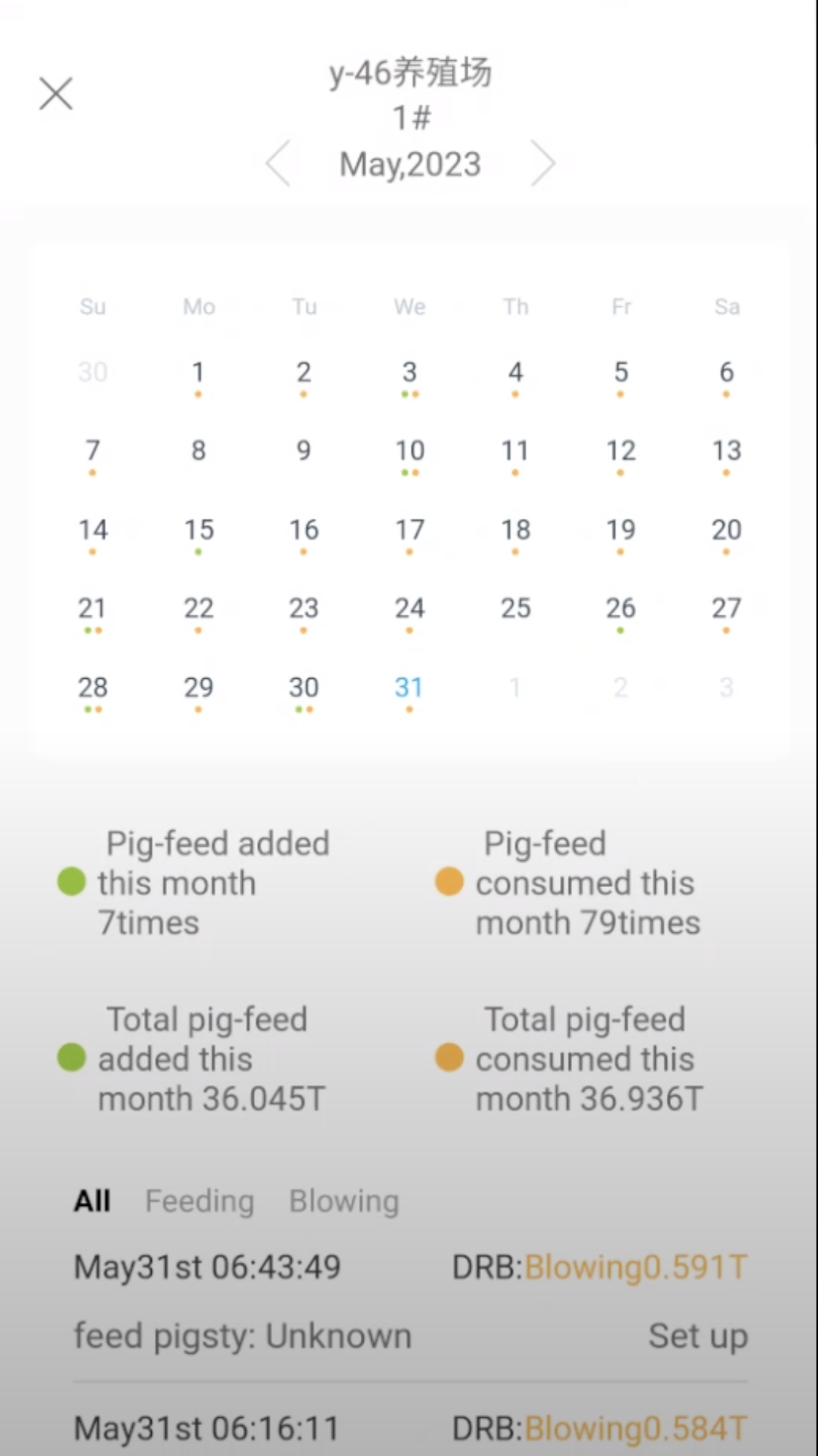

From June 19th to 20th, 2024, the SWT team participated in the Ontario Pork Congress in Ontario, Canada, showcasing our technological innovation, the Smart Weighing System for Feed Bin. This exhibition not only highlighted the professionalism of our products but also reflected the enthusiasm and proactive attitude of our team.

Over the two-day event, SWT's booth became a hub of interaction. Our team members engaged in pleasant exchanges and discussions with equipment suppliers and feed mill suppliers from various regions. These conversations not only promoted our innovative intelligent weighing technology solutions but also deepened our connections within the industry, thus enhancing our prospects in the Canadian market.

The congress provided an excellent opportunity to demonstrate the advantages of SWT's Smart Weighing System in terms of accuracy, precision, and timeliness. Our silo weighing system stood out for its efficiency and cost-saving features, attracting widespread attention from attendees. Additionally, the technical advancement and ease of operation of our product were highly praised by industry experts.

SWT is committed to supporting the global development of the swine industry through continuous technological innovation. We look forward to future exhibitions where we can continue to discuss and promote the sustained progress of the swine industry with leaders and innovators in the field.

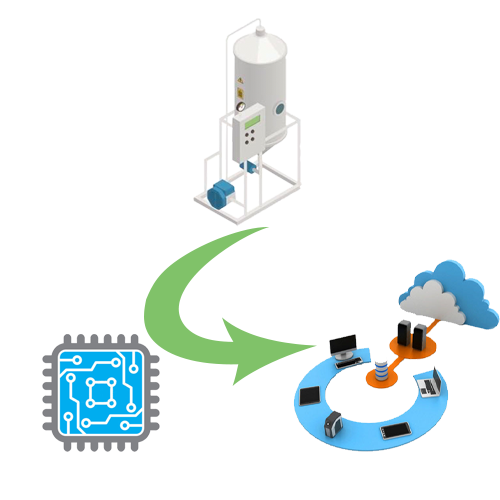

Load Cell Specially Designed for Livestock Industry

Intelligent Controller Embedded with Algorithms Chip

Cloud Computing System

Deliver precise visualization of silo data and enable accurate feed production plan, preventing interruptions due to feed shortage or waste due to feed overflow.

Demonstrate accurate data comparison between feed producers and breeding farms, monitor and alarm for any data deviation in real time, and enable farms to take proactive actions.

Monitor breeding operations through Cloud computing of feed consumption data, provide an assistive tool for breeding facilities inspection, and build a solid data basis for breeding farm management.

Smart push notifications for abnormal situation. Whether it is a hardware failure of the load cell/intelligent controller, or a data deviation of feed inflow/outflow, the Cloud computing system will send prewarning and remind breeding farm managers for timely troubleshooting and equipment maintenance.

Simple & Easy DIY installation: each silo generally has 4, 6, or 8 stand bars; installation of WitGood load cells, as simple as shoe-wearing, can be finished in three hours by two staff per empty silo, no need to use cranes or to dismantle existing wirings.

Dynamic real-time calibration: Through the Deep Learning of AI, each load cell can be calibrated in real-time, and data deviation arising from various disturbing factors can be rectified, relieving farms from burdens of manual calibration and struggles with data fluctuations.

Provide reliable feeding analysis & reports to breeding farm managers, assisting them to setup operation standards and adjust operation strategies accordingly.

Inaccurate Data Reading of Load Cells

No Reliable Data basis for Operation Analysis (often a guesswork)

High Labor Cost on Calibrations, Installation, and Maintenance, Tedious Operation Process

Load Cells' Exposure to Various Uncontrollable Factors (Temperature, Humidity, Air pH etc.)

Unable to Meet Complex Data Management Needs in Transition to Smart Agriculture

Silo weighing products, such as load cells and weighing modules, operate on the principle of strain gauge technology. A strain gauge is a device used in smart agriculture equipment that measures the strain (deformation) of an object. When force is applied to the object, it causes a change in the object’s shape, which the strain gauge measures as a change in electrical resistance.

In the context of silos, load cells are installed at the base or support points of the silo. When the silo is filled, the weight of the contents causes a deformation in the load cells for silos. This deformation is detected by the strain gauge, which then converts it into an electrical signal. The signal is proportional to the force applied, which in this case, is the weight of the silo’s contents.

This signal is then sent to a digital indicator or a control system, which interprets the signal and displays the weight. This allows for real-time monitoring of the silo’s contents, ensuring accurate inventory management and preventing overfilling or underfilling.

Moreover, modern silo weighing products often come with additional features such as temperature compensation, which adjusts the measurements for variations in temperature, and overload protection, which prevents damage to the load cells from excessive weight.

In essence, the science behind silo weighing products like weighing modules are a combination of mechanical engineering and electronics, providing a reliable and accurate solution for weight measurement in silos.

WitGood Intelligent Silo Weighing System applies next generation technologies including Intelligent Algorithms, Cloud Computing, and Smart IoT platforms, delivers precise weighing data without tedious manual calibration, and satisfies the complex data management needs of smart livestock farming.

WitGood Silo Weighing Products are industry-leading solutions designed to accurately measure the weight of materials stored in silos. These high-quality silo weighing systems provide real-time data, enabling efficient inventory management and process control. Built with advanced technology and silo level monitoring system, WitGood's products ensure precise measurements, regardless of environmental conditions or the type of material stored. This silo weighing system is easy to install, durable, and requires minimal maintenance, making them a reliable choice for industries such as agriculture, construction, and manufacturing. With WitGood Silo Weighing Products, businesses can optimize their operations of silo monitoring and make informed decisions based on accurate weight data.

Embedded with the integrated chip of intelligent algorithms power, intelligent controllers can rectify the data deviations caused by common disturbing factors, monitor each load cell for weighing in real-time, and provide a reliable data basis for complex farm management analysis. No competition to SWT algorithms in the market now.

Online Load Cells

Along with paid time off, a flexible work schedule, and the ability to work remotely, we also foster professional development and provide opportunities for career growth.

1-437-268-7072

Whether you are in layers farming or broiler farming business, WitGood's intelligent silo weighing system can provide customized digital and AI-based smart agro solutions that automatically measure and controls the amount of feed intake. This smart poultry system consists of load cells, a control unit with a digital display, and a cloud processing platform.

WitGood system uses high-precision load cells to measure the weight of feed as it flows into or out of the silo. The load cells automatically transmit the weight data to the control unit, which then calculates the amount of feed consumed. This data is shown on a digital display and transmitted wirelessly to computers or mobile devices in real time.

With an intelligent algorithm model combined with intelligent tracking & filtering algorithms, and cloud computing, WitGood digital agriculture solutions enable poultry farmers to:

Obtain accurate feed data

All major field interference factors including temperature, humidity, wind, and environment PH value, etc. are filtered out, with the power of WitGood intelligent algorithms and the deep learning capabilities of AI, trained by its +100,000 online load cells

Monitor feed dynamics in real time

WitGood smart agro solutions allow for real-time monitoring and control of the feeding process, facilitating adjustments as needed.

Detect abnormal feed data and equipment malfunctions proactively

Smart push notifications will be sent to both onsite staff and farm management once the WitGood system detects any abnormal situation so that problems can be addressed immediately.

Calibrate load cells via WitGood App effortlessly

With digital agriculture solutions, the need for onsite manual calibration is eliminated, avoiding complex processes, reducing labor costs, and minimizing operational disruptions.

Get timely and reliable “feed to meat”, and “feed to egg” ratios on each batch of poultry

WitGood system can collect and analyze feeding data, providing valuable insights for optimizing feed formulation and animal performance. This digital agriculture solution ensures that each animal receives the desired amount of feed, minimizing waste and ensuring optimal nutrition. By ensuring accurate and consistent feed intake, the system can contribute to better animal health and productivity.

Gain a powerful digital tool for comprehensive poultry farming management

WitGood system makes it easy to generate charts and reports on feeding behaviors at different production stages of a batch of poultry, or to compare different batches raised on the farm, assisting farmers in feed management and production planning. With its compatibility with other IoT devices, WitGood offers a smart tool for future poultry farming.

In summary, the WitGood system will help poultry farmers to:

Save cost on both feed and weighing equipment maintenance

Minimize feed waste, ensure optimal nutrition, and better poultry health and productivity

Enjoy the visualization and digitalization of smart poultry farming

Hainan State Farm (HSF) has deployed several hundred sets of WitGood intelligent silo weighing systems. The farm is located in the southeast part of Hainan province, only 20km away from the coastline, with an annual average temperature of 25.6C.

In the past five years, WitGood systems in HSF have been delivering precise and stable results under such tropical monsoon oceanic climates, often accompanied by salt-fog corrosion.

Over 100 sets of WitGood system have been adopted by Yili farm under Xinjiang Production and Construction Corp. Yili, located in the north-west part of Xinjiang, is under a Temperate Continental Cold Climate with an annual average temperature of 6.5C, and the average temperature in Jan at -20C.

WitGood systems in Yili farm have been running successfully with no malfunction for three years.

Two-year warranty

Online support for DIY installations

7x24 online service support for free

Automatic upgrades of WitGood software and WitGood App

24-hour hardware monitoring services via a smart IoT platform

WitGood Intelligent Silo Weighing System stands out for its easy-to-use and low maintenance, which have earned us increasing customer recognition.

Based on the performance records maintained since its inception, the failure rate is minimal, and remote calibrations cost nothing. Furthermore, our load cells, powered by data feed management software, have delivered high-precision data reading and transmission over the past five years.

Once you get on board of WitGood system, follow the user’s guidelines and seek professional advice when needed. You will have peace of mind with our 7x24 online service support. There will be minimal cost on repair and maintenance.

Cloud computing system processes all data uploaded. Through Deep Learning of AI, each load cell can be managed and calibrated via WitGood APP or PC Web. With Cloud Computing, real-time push notifications will be sent, in case of a hardware failure or abnormal feed data deviation, enabling timely troubleshooting.

SWT Technology is set up with a vision to promote next generation technologies including AI, Cloud Computing and IoT in agriculture & livestock industry, help farming enterprises build reliable database and strong data management capabilities, so to proactively embrace the challenges in the transition to smart agriculture.

Joint market research and marketing planning, expo and conference presentations.

From June 5th to 6th, 2024, Joy Zheng, CEO of SWT, participated in the World Pork Expo held in Des Moines, Iowa, USA. At the event, SWT showcased our innovative technology, the Smart Weighing System for Feed Bin, which attracted widespread attention and interest from numerous exhibitors and farmers due to its exceptional precision, accuracy, and efficiency. Many attendees stopped by for consultations and to collect information.

June in Des Moines is notoriously hot, yet the global pork industry expo was exceptionally lively. SWT’s Smart Weighing System stood out among many similar products, demonstrating remarkable competitiveness with its time-saving, labor-saving, and cost-effective features. At a pivotal moment in the development of the swine industry, our product not only enhanced operational efficiency but also reduced costs, proving its unique value and potential in the market.

SWT is committed to advancing the swine industry through continuous technological innovation in digital farm management. Our outstanding performance at the World Pork Expo further solidified our industry position, showcasing our crucial role in the global pork supply chain.

From June 5th to 6th, 2024, Joy Zheng, CEO of SWT, participated in the World Pork Expo held in Des Moines, Iowa, USA. At the event, SWT showcased our innovative technology, the Smart Weighing System for Feed Bin, which attracted widespread attention and interest from numerous exhibitors and farmers due to its exceptional precision, accuracy, and efficiency. Many attendees stopped by for consultations and to collect information.

June in Des Moines is notoriously hot, yet the global pork industry expo was exceptionally lively. SWT’s Smart Weighing System stood out among many similar products, demonstrating remarkable competitiveness with its time-saving, labor-saving, and cost-effective features. At a pivotal moment in the development of the swine industry, our product not only enhanced operational efficiency but also reduced costs, proving its unique value and potential in the market.

SWT is committed to advancing the swine industry through continuous technological innovation. Our outstanding performance at the World Pork Expo further solidified our industry position, showcasing our crucial role in the global pork supply chain.

At PC interface, cloud computing system generates multiple Reports and Charts of farm operations and highlights all abnormal data for proactive actions. Via WitGood App, cloud computing system offers easy to follow display and real-time push notifications, making a handy monitoring tool for onsite staff.

Provinces in China

We would love to have you on the team!

We’re always looking for top talent to join us.

Check out our open positions below, or feel free to contact us.

Step 1: Remove the existing Base Plate

Step 2: Mark the Cutting Line

Step 3: Cut the Silo Stand Bar

Step 4: Clean the Ground

Step 5: Drill Holes in the Silo Stand Bar

Step 6: Install WitGood Base Plate and Load Cell

Final Step: Tighten up the Load Cell

Wire connect WitGood Intelligent Controller with all load cells of the silo

Turn on the Intelligent controller

Set the display to zero

Download WitGood App and login, gain access to WitGood smart platform right away

Now enjoy the visualization and digitalization WitGood system brings to you.

WitGood provides an integrated IoT platform, accessible to other IoT applications such as environment control system, surveillance system, and smart water/electricity meter etc. It can easily fit into existing farm management system and supports various networking protocols.

Innovation

Our investment have been heavily putting into talents acquisition and IT infrastructures development. Innovation is the heart and soul of our business.

Integrity

We work with the passion to promote next generation technologies to livestock farming, the most traditional business often left behind by new technologies, even though this endeavor involves with great challenges.

Growth

We believe that business sustainability lies in creating growth opportunities for both employees and customers.

We strive to create a culture that fosters trust, inclusivity, and respect in a welcoming and fun work environment. By doing so, we build stronger connections between our employees, our customers, and the community around us.

Training both onsite and online, 7x24 technical support.

We are thrilled to announce that we will be exhibiting at the 2024 World Pork Expo from June 5 to June 6. Come find us at the Iowa State Fairgrounds in Des Moines, IA.

You can visit us at Booth #1042,where we look forward to connecting with you. See you there!

Countries Overseas

WitGood Intelligent Silo Weighing Solution is an innovative offering uniquely designed for Livestock Industry. Smart weighing system filters out all disturbing factors by applying Intelligent Algorithms, achieves significantly better data accuracy with the power of Cloud Computing and Deep Learning, and ensures optimal automatic weighing system performance with a new smart IoT monitoring platform.

In the rapidly evolving world of agriculture, the integration of technology has been a game-changer, particularly in the realm of feed management. SWT, a pioneer in smart agriculture equipment, is at the forefront of this revolution, offering advanced feed management systems that are transforming the way farmers approach livestock nutrition and farm efficiency. These feed management systems, a cornerstone of digital farm management, are not just about automation; they're about smarter, more sustainable farming practices. Let’s delve into how these innovations are reshaping the agricultural landscape.

One of the most significant impacts of feed management systems is their ability to provide precision nutrition. By analyzing the specific dietary needs of livestock based on various factors such as age, weight, and health status, these intelligent weighing technology systems can tailor feed ratios for optimal health and productivity. This precision not only enhances animal welfare but also maximizes feed efficiency, reducing waste and lowering costs for farmers.

The synergy between feed management systems and other smart agriculture equipment is a testament to the interconnected future of farming. These feed management systems can seamlessly communicate with automated feeding machinery, ensuring that the precise amount of feed is distributed at the right times. Moreover, integration with broader farm management software allows for a holistic view of farm operations, enabling better decision-making and resource allocation.

At the heart of digital farm management is the ability to monitor operations in real time. Feed management systems equipped with sensors and IoT (Internet of Things) technology provide continuous data on feed consumption and animal health. This wealth of feed management system information allows farmers to make immediate adjustments and predict future needs, ensuring that their operations are both responsive and proactive.

Sustainability is a critical concern in modern farming, and feed management systems play a crucial role in promoting eco-friendly practices. By optimizing feed usage and reducing waste, these feed management systems help lower the environmental footprint of livestock farming. Furthermore, efficient feed management contributes to better manure management and reduced greenhouse gas emissions, aligning farm operations with global sustainability goals.

The adoption of feed management systems is not just about improving farm operations; it's also about economic resilience. By streamlining feed management processes, farmers can achieve significant cost savings, improve livestock productivity, and enhance product quality. This economic advantage is crucial in an industry facing fluctuating market prices and increasing competition. As such, feed management system are not merely a technological investment but a strategic financial decision for the future of farming.

In conclusion, the revolution brought about by feed management systems in agriculture is multifaceted, touching on aspects of efficiency, sustainability, and economic viability. SWT's commitment to advancing smart agriculture equipment and digital farm management solutions is paving the way for a future where farming is not only more productive but also more sustainable and responsive to the global challenges of food security and environmental conservation. As we look ahead, it's clear that the future of farming lies in the intelligent integration of technology, and feed management systems are leading the charge.

In the rapidly evolving landscape of the modern livestock industry, the value of accurate feed flow data cannot be overstated. It holds the key to unlocking efficiencies and optimizing operations across the entire supply chain, from feed production to livestock feeding and transportation. However, the industry faces significant challenges in harnessing this potential, primarily due to issues with data accuracy, integration hurdles, and the limitations of current systems in providing real-time data acquisition. Recognizing these critical pain points, our IT team has embarked on a mission to develop robust IT infrastructures designed to empower the livestock industry with enhanced cost control capabilities and operational efficiencies.

Our research and development efforts are strategically focused on three core areas:

Precision Management System for Livestock Farming Group: This system aims to revolutionize livestock management by providing precise, real-time data on feed consumption, animal growth rates, and health indicators. By leveraging advanced analytics and IoT technologies, the advanced cloud computing system enables farm managers to make informed decisions, optimize feed usage, and improve overall herd health and productivity.

Feed Production Management and Data Integration System: Understanding the complexities of feed production, this system is designed to streamline operations, from ingredient procurement to final feed production. AI monitoring ensures seamless data integration throughout the feed production process, promoting both accuracy and transparency.This, in turn, helps in reducing wastage, managing costs more effectively, and ensuring the production of high-quality feed.

Machinery Operation and Maintenance Management System for Feed Production: Recognizing the critical role of machinery in feed production, this system focuses on optimizing machinery usage and maintenance. By monitoring machinery performance in real-time, predicting maintenance needs, and managing operation schedules, the system aims to minimize downtime, extend machinery lifespan, and reduce operational costs.

Through these targeted R&D initiatives, our IT team is committed to addressing the industry’s challenges head-on. By providing innovative solutions that ensure data accuracy, facilitate seamless data integration, and enhance real-time data acquisition capabilities, we are paving the way for the livestock industry to achieve unprecedented levels of cost control and operational efficiency across all aspects of livestock feeding, feed production, and feed transportation. Our goal is to transform data into a powerful management tool that drives productivity, sustainability, and profitability in the modern livestock industry.

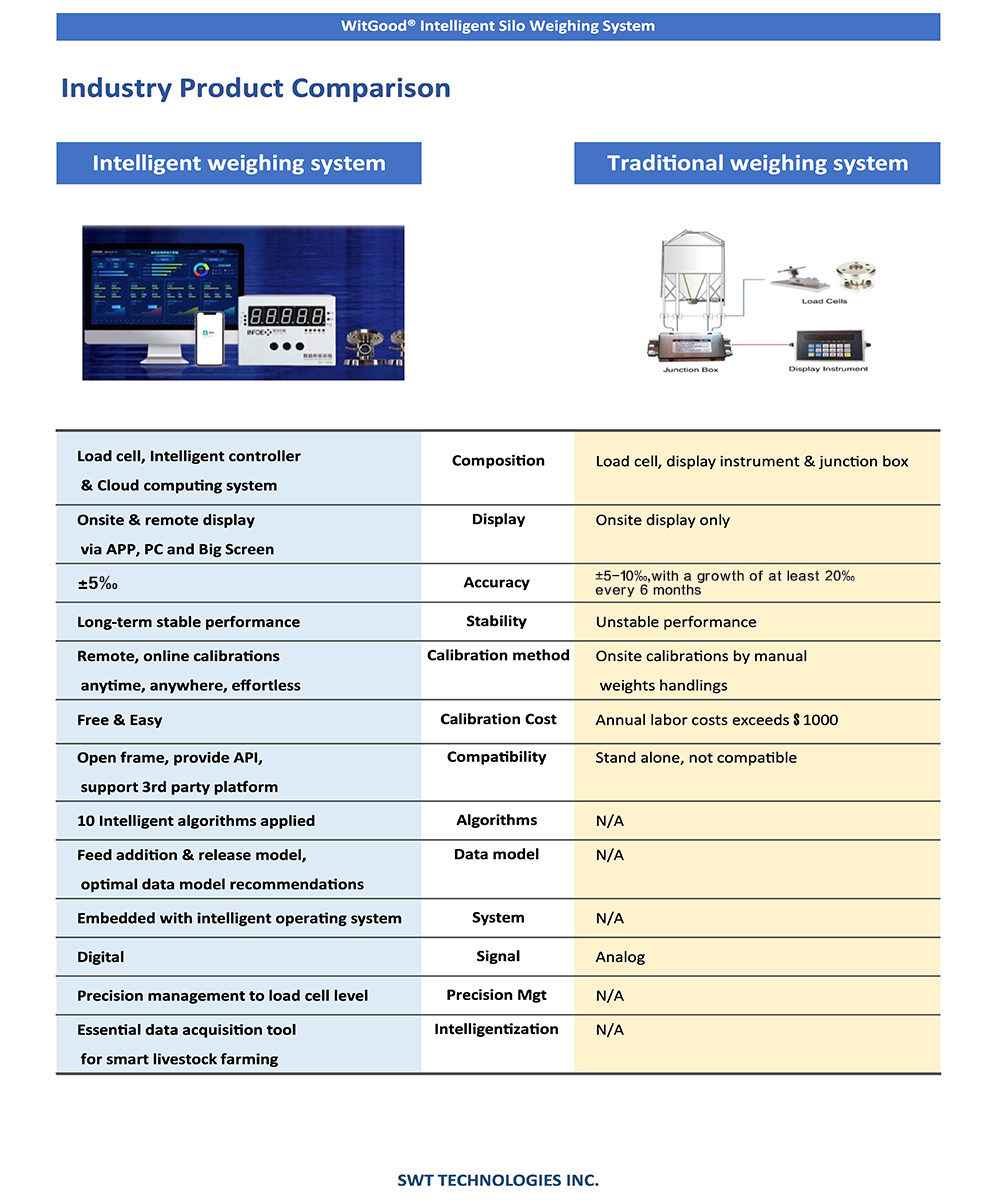

Super Durability and Precision: The WitGood Intelligent Weighing System is composed of highly integrated equipment with intelligent algorithm power, minimizing the malfunction rate caused by too much equipment of traditional feed management systems. The smart weighing system is proven to last for +5 years with an error rate of ±5‰, compared to the traditional system error rate with a growth of at least 20‰ every 6 months.

Lower cost: Equipped with cutting-edge technologies, WitGood's automatic weighing system can calibrate at any time via its App. Silo weighing systems can also detect and alert users to potential issues such as hardware malfunction or feed shortage/overflow. This proactive digital farm management is not common in traditional systems, which often leads to costly manual calibrations, hard-to-control feed waste, and expensive operational downtime.

Improved efficiency: WitGood Smart weighing system prepares livestock farming with handy digital management tools. Real-time feed statistics and smart push notifications of feed management systems are available at your fingertips, which have highly improved farm operation efficiency. On the contrary, traditional systems do not support automatic data transmission, lagging in meeting the complex data-driven management needs of modern farms.

Easy integration: The WitGood system is designed for seamless integration with other IoT systems, and supports various networking protocols, making it a versatile tool for multiple farm management functions. In contrast, traditional systems are often standalone units and are not compatible with other equipment or software, limiting their functionality.

In summary, WitGood Intelligent Silo Weighing System outperforms traditional silo weighing systems in terms of super durability and precision, lower cost, improved efficiency and easy integration.

“We have been using the Intelligent Silo Weighing System for several months now and it has been a game-changer for our business. The system has provided us with accurate and real-time weight measurements, allowing us to effectively monitor and control our inventory levels. The automated alerts and notifications have helped us prevent overfilling or underfilling of our silos, saving us time and money. The system’s user-friendly interface and easy integration with our existing software have made the implementation seamless. We are extremely satisfied with the performance and functionality of this system.”

In the realm of precision agriculture and efficient feed management, the Witgood Silo Weighing System by SWT stands out as a beacon of innovation and reliability. This advanced system is designed to offer unparalleled accuracy in silo weighing, ensuring that farmers and agricultural businesses can monitor and manage their resources more effectively. At the heart of its operation are three critical components: Load Cells for Silos, an Intelligent Controller embedded with an Algorithms Chip, and a Cloud Computing system. Let’s delve into the functionalities and benefits of these essential elements.

The foundation of any silo weighing system lies in its ability to measure weight accurately, and this is where Load Cells for Silos come into play. These precision instruments are engineered to withstand the heavy loads and environmental challenges typical of agricultural settings. By converting force into electrical signals, load cells for weighing machines, including silos, provide real-time data on the quantity of material stored. This information is crucial for inventory management, planning, and ensuring the optimal use of resources.

The brain behind the Witgood Silo Weighing System is its Intelligent Controller, which is equipped with a state-of-the-art Algorithms Chip. This silo monitoring component is responsible for processing the data received from the load cells, applying advanced algorithms to interpret the signals accurately. The intelligent controller facilitates real-time decision-making, allowing for immediate adjustments to be made based on the silo’s contents. Its embedded algorithms shield the load cell data from external factors, analyze storage conditions, and even alert users to potential issues before they become problematic, ensuring smooth and efficient silo management.

In today’s interconnected world, the ability to access and analyze data remotely is invaluable. The Witgood Silo Weighing System incorporates a Cloud Computing system to meet this need. This platform enables the storage and analysis of vast amounts of data generated by the silo weighing process. Users can access this information from anywhere, at any time, via a secure internet connection. The cloud computing system not only facilitates easy data retrieval and analysis but also allows for seamless integration with other digital farm management tools. This connectivity ensures that decision-makers have a comprehensive overview of their operations, enabling better strategic planning and resource allocation.

The true strength of the Witgood Silo Weighing System lies in the synergy between its main components. The precision of Load Cells for Silos, combined with the intelligence of the controller and the accessibility provided by cloud computing, creates a robust system that enhances the efficiency and productivity of agricultural operations. This integrated approach ensures that users can rely on accurate, actionable data to make informed decisions, ultimately leading to improved outcomes for their businesses.

The Witgood Silo Weighing System by SWT smart agriculture company represents a significant advancement in agricultural technology. Its main components—Load Cells for Silos, an Intelligent Controller embedded with an Algorithms Chip, and a Cloud Computing system—work in harmony to provide a comprehensive solution for silo weighing and management. By leveraging these technologies, agricultural professionals can achieve greater accuracy, efficiency, and control over their operations, paving the way for a more sustainable and profitable future in farming.

“The Intelligent Silo Weighing System has greatly improved our operations at our manufacturing facility. The accuracy and reliability of the system have exceeded our expectations. It has helped us streamline our inventory management and optimize our production processes. The user-friendly interface and real-time data monitoring have made it easy for our team to make informed decisions. We highly recommend this system to any farm looking to enhance their weighing and inventory management capabilities.”

SWT Technologies Inc’s CEO Joy Zheng was among the prominent attendees at the 2023 London Farm Show on March 8th, engaging with industry leaders and innovators at one of the largest indoor farm show in Eastern Canada.

The London Farm Show, held annually, is a beacon for agricultural advancements, showcasing the latest in farm technology, software, and sustainable farming practices. It brings together thousands of farming professionals, providing a platform to discuss trends, challenges, and opportunities within the agriculture sector.

This year's event was marked by the presence of SWT’s CEO, who took the opportunity to explore the numerous exhibits and participate in discussions focused on the future of smart agri technology. The highlight of the visit was a warm and engaging conversation with Mr. Dave Smardon, the esteemed CEO & President of Bioenterprise. Their exchange centered on potential collaborations and innovations that drive the agricultural industry forward.

Feed cost accounts for +70% of the breeding operation costs. Data on feed consumption plays big part in the Profit and Loss analysis of breeding operation. Accurate and real-time data of silo feed flow is of the most importance and greatest concern to farm managers.

Feeds are stored in bulk in silos outside the raising houses. The capacity of each silo is in line with its breeding scale, usually at a level of 1-2 days’ consumption (with a volume less than one day, extra workload for feed transportation will incur, while with a volume more than 2 days, the feed freshness will be compromised). The feed volume in the silo keeps changing due to its centralized addition and real-time consumption.

Silos with a height of +5m and weight of 5~40 tons are usually installed in the open air, big errors in data reading (+-10%) are common & often due to many reasons:

1. The load cell under constant pressure tends to experience fatigue and lose sensitivity from time to time, and presents big errors in data reading

2. Changes in season, temperature and climate (wind, rain, and snow) often cause changes in silo shape and position, leading to inaccurate data reading.

3. The vibrations of pipes for feed inflow/outflow, big conveyors or other equipment often cause data reading to jump, making it hard for sensors to get valid reading

Silo-weighing data acquisition is so crucial for modern breeding farms, but the weighing systems commonly used today cannot provide farm managers with an accurate and reliable data basis for performance analysis due to big weighing errors, costly and time-consuming manual calibration, and inaccurate data reading and transmission.

●1st Generation:

traditional weighing equipment, an electronic scale composed of load cells and display instrument;

●2nd Generation:

with data transmission function, composed of load cells, display instrument and DTU (Data Transmission Unit);

●3rd Generation:

integrated with data collection, processing, and transmission capabilities, and powered with smart algorithms, composed of Load Cells, Intelligent Controller and Cloud Computing.

WitGood is the 1st Intelligent Silo Weighing System,Widely Adopted by Livestock Industry.

WitGood Intelligent Silo Weighing Solution applies next generation technologies including Intelligent Algorithms, Cloud Computing and Smart IoT Platform, delivers Precise weighing data without tedious manual calibration, and solves all problems derived from the traditional weighing system.

Except WitGood, all other prevailing brands such as Mettler Toledo of Switzerland, Scaime of France, and HBM of Germany adopt traditional weighing system.

WitGood satisfies the needs of modern breeding farms and have been successfully adopted by +100 agriculture enterprises across China.

Real-time data reading and transmission.

Error rate less than 0.5%.

Multiple intelligent algorithms are applied to improve data accuracy.

In the rapidly evolving landscape of agriculture, smart farm technology has emerged as a beacon of efficiency and sustainability. Among these innovations, intelligent bin weighing systems stand out, offering a seamless way to monitor and manage resources. This technology is not just a tool but a revolution, transforming the way farms operate, from small family-owned businesses to large-scale agricultural enterprises. Let’s delve into how these systems are reshaping the world of smart farming.

At the heart of smart farming startups is the silo weighing system, a technology designed to provide precise measurements of materials stored in bins. This system is crucial for managing feed, grain, and other agricultural inputs, ensuring that farmers can monitor their stock levels in real-time. By integrating bin weighing into their operations, farmers can significantly reduce waste, improve inventory management, and enhance overall farm efficiency.

Sustainability is a key concern in today’s agricultural practices. Intelligent bin monitoring systems play a pivotal role in achieving sustainable goals by allowing farmers to track consumption patterns, predict demand, and adjust supply accordingly. This not only minimizes the risk of overstocking and waste but also ensures that resources are utilized in the most efficient manner possible.

One of the most significant benefits of adopting a silo weighing system is the substantial increase in farm productivity. By providing accurate data on stock levels, these systems enable farmers to make informed decisions quickly, streamline operations, and prevent downtime. The ability to monitor bin contents in real-time also helps in planning the logistics of supply chain management, further boosting productivity.

While silo weighing systems are a cornerstone of smart farm technology, they represent just one aspect of the broader ecosystem. Today’s smart farms leverage a range of technologies, including automatic feeding system, remote automatic monitoring, and data analytics, to optimize every facet of farming. Intelligent bin weighing systems integrate seamlessly with these technologies, creating a cohesive and highly efficient agricultural model.

The future of farming is undeniably smart. As smart farming startups continue to innovate, technologies like intelligent bin weighing system will become increasingly sophisticated and accessible. These advancements promise to further enhance the precision, sustainability, and profitability of farming, paving the way for a new era of agriculture that is smarter, more resilient, and more productive than ever before.

In conclusion, intelligent silo weighing systems are more than just a component of smart farm technology; they are a catalyst for change. By enabling precise monitoring, promoting sustainability, and boosting productivity, these systems are helping to navigate the complex world of modern agriculture. As we look to the future, the role of intelligent bin weighing in smart farming will undoubtedly continue to grow, driving the industry towards a more efficient and sustainable future.

In the field of animal farms, the silo weighing system is like a powerful assistant, assisting enterprises to achieve efficient and accurate material management. However, there is a dazzling array of products on the market, how to choose a silo weighing system that really suits you? This article will be from four key aspects, for you to reveal the secret of choosing a silo weighing system.

Before choosing a silo weighing system, farms first need to have a clear understanding of their needs. This includes understanding the feed bin volume to be measured, the accuracy requirements, the working environment, and regulatory standards. Only by clarifying these needs, can we target the selection of a suitable system to ensure that it can be perfectly integrated into the production process of the enterprise.

Accuracy and stability are important indicators of silo weighing system performance. An excellent silo weighing system should be able to provide accurate and stable measurement data in a variety of environments, to ensure that farms can accurately grasp the feed situation, to provide strong support for ordering decision-making. Therefore, when choosing a system, we should pay attention to its measurement technology, sensor quality, calibration maintenance, and other aspects of performance.

In an animal farm environment, silo weighing systems need to withstand a long period. Therefore, it is crucial to choose a system with high durability. In addition, high-quality service support is not to be ignored. We should choose a supplier who can provide timely and professional service to ensure that problems encountered during use can be resolved quickly, ensuring production continuity and stability.

In conclusion, choosing the ideal silo weighing system requires comprehensive consideration of many aspects. Through in-depth understanding of the requirements, the pursuit of accurate measurement, and the consideration of durability and service, we can select the silo weighing system that best suits our own enterprise and provides strong support for material management.

SWT has significant market advantages in silo weighing systems. Its products are well received in the market due to their high accuracy, high stability, and strong compatibility. SWT focuses on technological innovation and continuously introduces new intelligent and automated weighing systems to meet the diversified needs of customers. At the same time, SWT also provides a full range of after-sales service to ensure that customers receive timely and professional technical support in the process of use. With excellent product performance and perfect service system, SWT stands out in the silo weighing system market and becomes the industry leader.

As an Innovative Technology Provider and Reliable Business Partner, SWT Technologies Inc. strives to help livestock farmers digitalize feeding management, and optimize feed formulation and animal performance, so to achieve a smooth transition to Smart Agriculture.

Founded in Toronto in Nov. 2022, SWT, the smart farm solution company, the smart farm solution company aims to introduce and promote the WitGood system to Livestock farmers in North America. With expertise and passion in both the IT and livestock industries, our team has a deep understanding of farmers' challenges and a quick response to their R&D needs. With advanced algorithms, AI and IoT-based weighing machines achieve higher data accuracy through deep learning. WitGood weighing equipment has been proven to be super precise and durable even under extreme weather.

SWT technologies WitGood is the First Intelligent Silo Weighing System in the livestock industry, with distinctive precision and reliability outperforming all prevailing silo weighing systems in the market.

As a smart agriculture company, we have achieved rapid business growth thanks to WitGood's capabilities of

remote calibrations,

real-time feed consumption monitoring, and

compliance with strict safety & hygiene operation requirements post-pandemic.

Moreover, as a professional smart farm company, we can provide the advanced intelligent weighing technology of the WitGood Intelligent Silo Weighing System. if you are in need, welcome to contact us!

In the rapid development of the farming industry, feed management, as a key link, has a significant role to play in improving efficiency and effectiveness, and SWT has brought farmers an unprecedented management experience with its excellent feed management platform. What are the features of SWT's feed management platform? And what are the significant advantages?

SWT feed management platform integrates the Internet of Things, big data, and other advanced technologies to achieve real-time monitoring and intelligent management of feed inventory and usage. With just one click, farmers can easily obtain detailed information on the remaining amount of feed, the speed of use, and the feed intake of each animal. This intelligent management not only greatly improves management efficiency but also provides farmers with data support for scientific decision-making. Intelligent management plays an important role in improving efficiency and reducing costs, injecting new vitality into the sustainable development of the farming industry.

The feed management platform tailors precise feed formulas and feeding plans for each animal according to the differences in species, growth stages, and health conditions. This precise feeding method ensures that the animals get the right nutrition and promotes their healthy growth, thus maximizing the benefits of farming. Through precision feeding, the growth rate and yield of animals have been significantly improved, bringing considerable economic returns for farmers.

SWT feed management platform excels in cost control. The platform can automatically analyze feed consumption data and provide farmers with reasonable procurement suggestions to avoid inventory backlog and waste. According to farmers' feedback, after using the SWT feed management platform, their feed costs have been effectively controlled and the maximum use of resources has been achieved.

In summary, the SWT Feed Management Platform brings farmers an unprecedented management experience with its significant advantages of intelligence, precision, and cost control. Through the platform, farmers can easily achieve comprehensive optimization of feed management, improve farming efficiency, and promote the sustainable development of the farming industry. We believe that in the future, SWT feed management platform will continue to give full play to its outstanding advantages, create more value for the farming industry, and lead the industry towards a better future.

As an Innovative Technology Provider and Reliable Business Partner, SWT Technologies Inc. strives to help livestock farmers digitalize feeding management, help to optimize feed formulation and animal performance, so to achieve a smooth transition to Smart Agriculture.

In the past five years, WitGood system has been successfully applied to 100+ farm groups across 29 provinces in China. More than 100,000 online load cells have been installed. WitGood algorithms have achieved increasing data accuracy through the deep learning capabilities of AI. WitGood weighing equipments have been tested with extreme weathers and proved to be super precise and durable.

In fact, WitGood is the first Intelligent Silo Weighing System in livestock industry, with distinctive precision and reliability that no other prevailing weighing systems can offer at present.

WitGood system delivers best performance under such circumstances as:

Temperature range: -40℃ to 85 ℃

Relative humidity: < 85% RH, avoid strong corrosive air/gases.

Silos are important equipment for storing materials in farms, once the silos are out of material or topped up in the production process, it will cause great loss to the enterprise. Therefore, it is very important for farms to accurately measure the material level of silos. This article will discuss in detail the importance of load cells for silos in silo management.

Load cells for silos can be used to record clean grain after cleaning, dry grain after drying, grain out, and distribution, among other things. Tank weighing systems consisting of weighing modules, weighing junction boxes, and weighing instruments are used for precise measurements when storing, loading, or unloading bulk solids or liquids. By installing a silo on top of the weighing module, the weight inside the container can be determined very accurately and the data can be easily transferred to an external data system.

In industrial production, silos are important equipment for the storage of raw materials, and their inventory management is directly related to production efficiency and cost control. Load cells for silos make it possible to monitor silo inventories more accurately and in real time. Monitoring the weight of raw materials in silos in real time with a silo load cell system allows production managers to accurately manage inventory and avoid production delays or waste due to imbalanced stock levels.

With load cells for silos, companies can automate the management of silo materials. When the material reaches a preset threshold, the system will automatically trigger an alarm or automatic replenishment, reducing manual intervention and improving management efficiency. At the same time, the weighing data from load cells for silos can be integrated with other management systems (e.g. ERP, MES, etc.) to realize comprehensive sharing and collaboration of material information.

Overloading of silos or excessive accumulation of materials may lead to damage or collapse of the silo structure, posing serious safety risks to personnel and equipment. With load cells for silos' real-time monitoring of material weights, companies can identify and address potential safety hazards on time, ensuring the safe and stable operation of their silos. In addition, load cells for silos can also monitor the structural stability of silos, providing a strong guarantee for the safe operation of silos.

In addition to silos, load cells for silos also play an important role in the field of culture towers, silos, and reactors, monitoring stock levels in real time and improving production efficiency. In the future, load cells for silos will develop in the direction of higher precision, stability, and intelligence, realizing remote monitoring and management, and improving production efficiency and management level.

Hainan State Farm (HSF) has deployed several hundreds sets of WitGood intelligent silo weighing system in the south- east part of Hainan province, only 20km away from the coastline, with annual average temperature at 25.6C.

In the past five years, WitGood systems in HSF have been delivering precise and stable results under such tropical monsoon oceanic climate, often accompanied with salt fog corrosion.

Over 100 sets of WitGood system have been adopted by Yili farm under Xinjiang Production and Construction Corp. Yili located in the north-west part of Xinjiang, is under Temperate Continental Cold Climate with annual average temperature at 6.5C, average temperature in Jan at -20C.

WitGood systems in Yili farm have been running successfully with no malfunction for three years.

Maximum weight a single load cell can take: 5 MT.

Normally, one Intelligent Controller can support one to eight independent load cells.

Feed cost accounts for +70% of the livestock breeding operations. So any cost saving on feed consumption contributes to the profit. For many years, livestock farms have been struggling with feed wastes and operation disruptions due to inaccurate & untimely feed data, which is inevitable by using traditional Silo Weighing systems.

WitGood offers Real-time & Accurate data on feed consumption, the most needed solution to livestock farms.

In farm feed management, the accuracy of silo weighing systems is crucial. In order to ensure accurate measurement and efficient operation, selecting the right load cells for silos becomes a key task. Load cells for silos need to be properly selected to maximize their performance.

Generally speaking, if the feed bin has several support legs, several sensors should be used. Load cells for silos range selection can be based on the scale's maximum weighing value, the number of sensors, the scale's self-weight, the maximum possible bias load and dynamic load and other factors to determine a comprehensive evaluation. In general, the closer the range of the load cells is to the load assigned to each cell, the more accurate the weighing will be.

The accuracy rating of load cells for silos includes technical specifications such as nonlinearity, creep, creep recovery, hysteresis, repeatability, and sensitivity of the sensor. When selecting load cells for silos, do not simply pursue high grade sensors, but consider both meeting the accuracy requirements of electronic scales and their cost.

Farm silos often face harsh working environments, as frequent disinfection can cause equipment corrosion, outdoor seasonal and day night temperature differences, as well as dust effects, all require load cells to have high tolerance.

Corrosive environment: This environment will cause load cells for silos elastomers to be damaged or short-circuited, etc., so you should choose sensors that have been sprayed on the outer surface or have a stainless steel cover with good corrosion resistance and good sealing.

Temperature: High-temperature environments will cause the sensor to experience weakened adhesive, aging, weld cracking, and structural changes in the elastomer's internal stress. In this case, it is necessary to select a high-temperature-resistant sensor. In addition, there must be heat insulation, water cooling, or air cooling devices.

Dust, humidity: For some sensors working in humid, dusty environment, should choose the diaphragm heat sleeve sealing or diaphragm welding sealing, vacuum nitrogen-filled sensors.

Where and how load cells for silos are installed will directly affect their measurement accuracy and stability. When selecting load cells for silos, it is important to consider the structural characteristics of the silo, the feed flow characteristics, and the ease of maintenance. Ensure that they can be easily installed in the right place and that they are easy to maintain and calibrate. In addition, load cells for silos should have a long service life and low maintenance costs in order to minimize later operating costs.

When choosing the accuracy of load cells for silos, the accuracy of the sensor should be slightly higher than the theoretically calculated value. Because the theory is often limited by objective conditions. Such as the silo's working environment is relatively harsh and other factors have a direct impact on the accuracy requirements of the load cells. Therefore, to improve the requirements from all aspects, but also to consider the economic benefits, to ensure that the purpose.

Feed addition and consumption analysis

Alert of abnormal situations such as feed release during addition, unusual feed waste, etc.

Feed consumption across livestock batches, and feed/meat ratio analysis across farms within one group, for timely analysis, forecasting, and monitoring.

This smart weighing system also supports the automatic generation of feed purchase orders, linking to their supply chain.

Silos, with a height of over 5m and weight of 5~40 tons, are usually installed in the open air. Big errors in data reading (+-10%) are common with traditional silo weighing systems, due to the following:

Load cells, under constant pressure, tend to lose sensitivity as time goes

Changes in seasons, temperature and climate often cause changes in silo shape and position

The vibrations of other surrounding equipment often at resonance make it hard for load cells to get valid reading

With the improvement of pig farming scale and intensification, the technology level of pig farm feeding management is getting higher and higher, more and more large-scale pig farms start to apply smart farming solutions. The use of intelligent feeding management system improves the level of animal welfare, and brings better economic benefits for pig farming enterprises. This article will introduce the advantages of smart farming solutions in pig farming.

Automated feeding systems are able to accurately calculate and distribute feed according to different growth stages and the actual needs of the pig. This precision feeding ensures that pigs receive the right amount of nutrients and avoids the overload or lack nutritional problems that can occur with traditional feeding methods.

Traditional pig farms require a lot of manpower for feeding, cleaning, and other tasks, while the automated feeding system greatly reduces this burden. The system realizes the automation of feeding, drinking, cleaning, and other work through preset feeding plan and automated control equipment. This not only saves a lot of labor costs, but also improves work efficiency, enabling the farm to run more efficiently.

By collecting and analyzing pig feeding data, growth data, and other information, the automated feeding system can provide scientific decision support for the farm. Based on the data provided by the system, managers can understand the growth status of pigs, feed consumption, and other information, so as to develop more reasonable breeding plans and feeding strategies. At the same time, the system is also able to predict the feed demand and growth trend in the coming period of time, providing strong support for the sustainable development of the farm.

The selection and design of feeding equipment in pig farms affects the feed intake of pigs. Suitable feeding equipment reduces the weight difference between pigs, meets the nutritional needs of pigs at all stages, reduces feed waste, improves production efficiency, and is of great significance to the sustainable development of pig farms. With the scale and intelligent development of pig raising industry, smart farming solutions have a broad application prospect.

WitGood is the 1st Intelligent Silo Weighing System,Widely Adopted by Livestock Industry.

WitGood Intelligent Silo Weighing Solution applies next generation technologies including Intelligent Algorithms, Cloud Computing and Smart IoT Platform, delivers Precise & real-time feed data without tedious manual calibrations, filters data deviation by applying intelligent algorithms, and solves all problems derived from the traditional silo weighing system.

WitGood satisfies the needs of modern livestock breeding farms and have been successfully adopted by +100 agriculture group enterprises.